Promotional

Advertise with your good name

Use these advantages:

- Individual printing, for example, with product name and Logo in CI-Colours

- Exact dosing and measurement using precision special scales defined by the customer

- Stimulation of incentive to purchase your product

- Increased recognition of your brand

- Stronger and more economical advertising effect

VITLAB specialises in printing high-precision plastic laboratory ware. Other companies can take advantage of this know-how to create products individualised with a logo, name or customized scale. They are ideally suited for use as promotional articles to boost product sales as well as for internal labelling.

They can be used anywhere where granulates, powders or liquids are used; for example, agriculture, laboratories, the food industry, the cleaning sector or in other industries using dyes and chemicals.

Manufacturing in our own production facility guarantees maximum efficiency and flexibility. A complex production process and comprehensive quality controls ensure that the print is long-lasting.

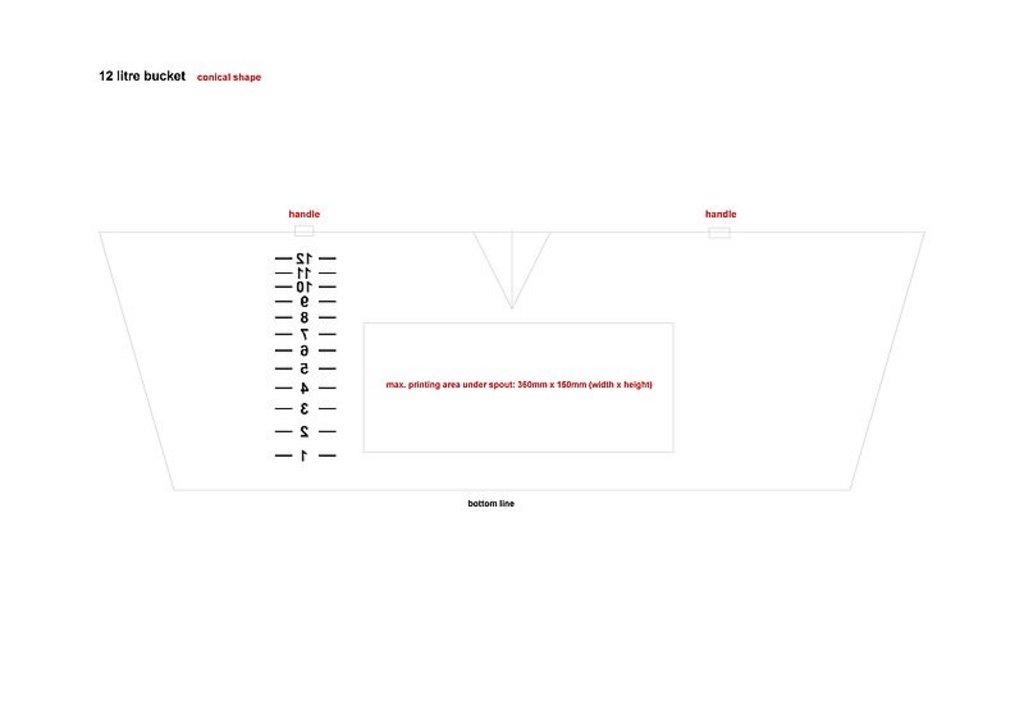

Print VITLAB® graduated beakers, measuring scoops, buckets and graduated cylinders for example with

- Your logo

- Your name

- Your customized scale

The shape, design and labelling of the products can be manufactured and printed according to your wishes.

VITLAB employs the screen printing process for customized labelling. All colours from the Pantone or HKS palettes can be printed.

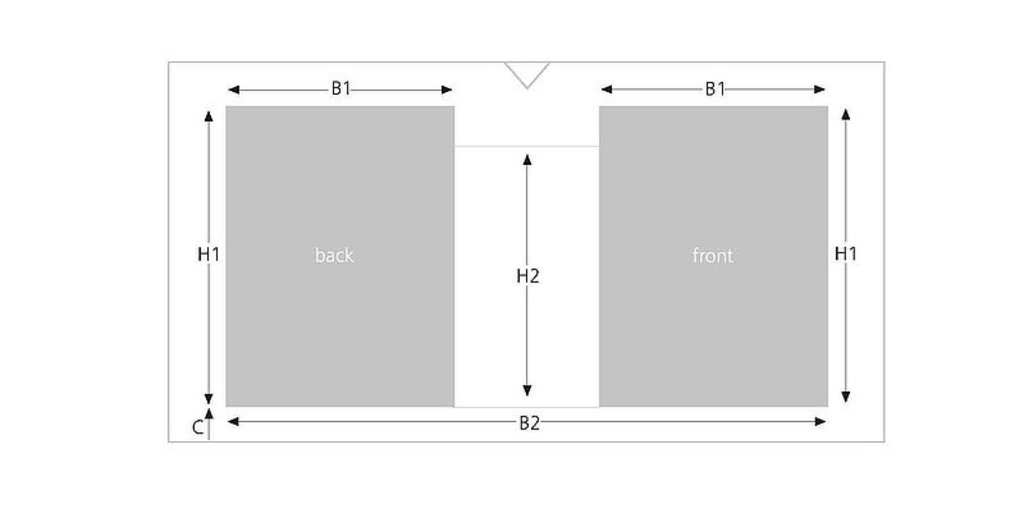

Depending on article type, shape and size, different printable areas are available for your individual design.

From telephone consultations to customer visits, VITLAB® Promotional offers high-quality full service. Layout proposals are included in the price. Proof samples can be ordered for an extra charge.

Printing Process

Reliable and long-lasting

Round, conical or flat imprint in screen printing or pad printing process with especially long lasting and vibrant print colours using the colour palette of Pantone or HKS create an advertising carrier of the very highest quality. Differing marking techniques such as laser imprint and hot embossing offer you a unique design.

In screen printing, the print colour is pressed onto the surface of the plastic article with a scraper through a finely meshed fabric (gauze). In the places which are not to be printed, the mesh openings of the fabric are closed so that colour cannot permeate them. Screen printing can be used to apply special print colours to flat and formed surfaces with especially clear contours. Using special techniques, such as the raster process, attractive graphic effects can be generated.

In pad printing, the colour is pressed into the lower-lying print image that is being printed. A silicone-rubber pad accepts the colour of the print image and applies it to the plastic article, similarly to a stamp. The benefit: Due to its elasticity, the pad adapts to the curvature of the surface, thereby ideally transferring the print image.

All colours used by VITLAB excel through good chemical resistance, high washing resistance and good friction resistance. This results in a long period of legibility. Pantone and HKS are colour systems in which selected colours are defined with unique descriptions.

The colour system according to Pantone was developed by the American Pantone Inc. in 1963 and has developed into a worldwide standard in the design and printing trade. It contains special colours which cannot be obtained in the common four-colour print process, and assigns these colours to unique numbers. The Pantone colour guide simplifies the selection of the desired colour.

The HKS colour guide was developed by three German printing and artists’ colour producers and is more widespread in the German-speaking regions. It defines 120 so called spot colours as well as 3520 colour tones, so that colours and colour shades can be reproducibly printed.

Download Print Templates

Have Questions?

T +49 6026 97799 42